Spring Cleaning for Your Conveyor System: Preparing for Increased Production

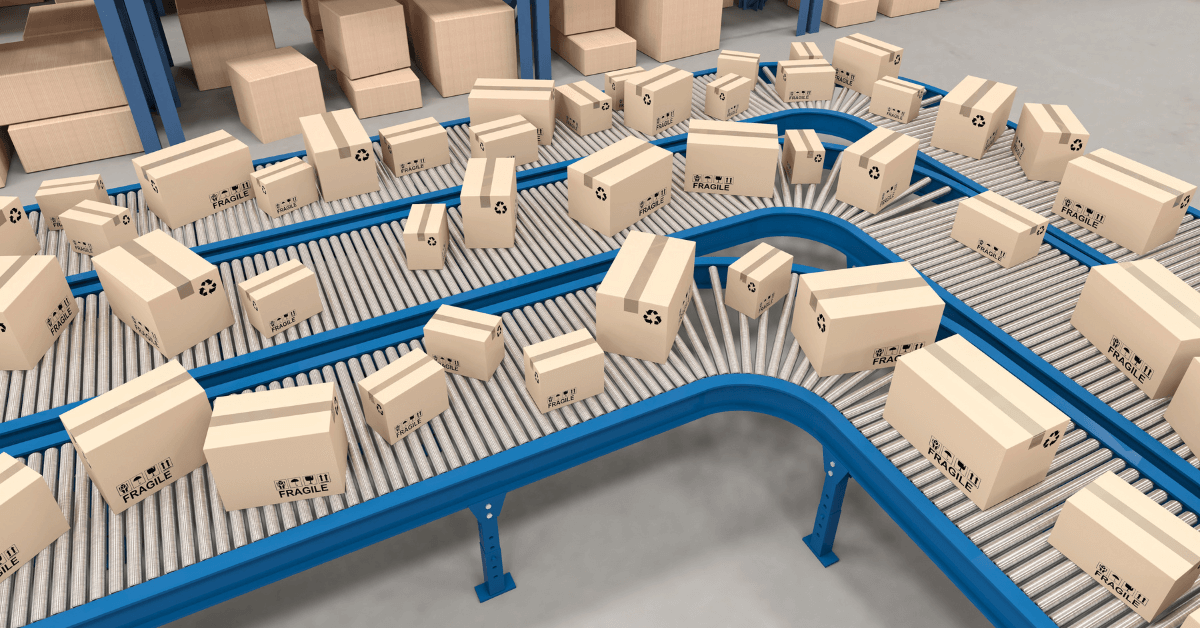

As the seasons change, so do the demands on your production lines. Spring is the perfect time to give your conveyor system the attention it deserves—especially when you’re preparing for a surge in production. Whether it’s due to increased seasonal orders or simply a much-needed maintenance check, spring cleaning your conveyor systems can make a significant difference in ensuring efficiency and reducing costly breakdowns.

Let’s explore why regular maintenance is crucial and how you can optimise your system for peak performance.

Why Spring Cleaning Matters for Your Conveyor System

Conveyor systems play a pivotal role in industries ranging from food production to packaging. However, like any machine, they need regular attention to keep them running efficiently. Dirt, dust, and debris can accumulate over time, causing wear on critical components like conveyor belts, rollers, and pulleys. These contaminants hinder system performance, leading to potential delays and breakdowns.

By addressing small maintenance issues before they become major problems, you not only save on repair costs but also extend the lifespan of your equipment, keeping it running smoothly through your busiest production periods.

The Risks of Neglecting Your Conveyor System

If regular maintenance is overlooked, several issues can arise, leading to disruptions in production. These include:

- Slower Operation: Dirt and debris slow down the movement of belts and rollers, making your system less efficient.

- Increased Energy Consumption: A poorly maintained system requires more power to operate, driving up energy costs.

- Shortened Equipment Lifespan: The continuous strain on parts that aren’t properly cleaned or maintained can cause them to wear out more quickly.

- Potential System Failure: In the worst-case scenario, malfunctioning components can cause the entire conveyor system to shut down, leading to costly downtime.

If any of these signs sound familiar, it’s time to give your system some attention. Let’s walk through how to ensure your conveyor system stays in top condition.

Step-by-Step Guide to Spring Cleaning Your Conveyor System

1. Safety First

Before performing any maintenance, always power down the system and lock out all energy sources. This is crucial to ensure the safety of everyone involved in the cleaning and maintenance process.

2. Inspect and Clean Your Conveyor Belts

The conveyor belts are the core of your system. It’s essential to keep them in top shape to maintain efficient operation. Start by inspecting the belts for signs of wear such as cracks, fraying, or the build-up of sticky substances that could lead to slippage.

To clean the belts, use a mild detergent and a soft brush to remove dirt and grime. For a deeper clean, consider using a specialised cleaner designed for conveyor belts. Our conveyor belts are built to handle tough conditions, and using the right cleaning products will help extend their lifespan.

3. Clean the Rollers and Pulley System

Rollers and pulleys are often overlooked but are critical for smooth belt operation. Over time, dirt and debris can accumulate on them, causing friction and wear. Clean the rollers and pulleys using a soft cloth or brush to ensure they’re free from build-up. Also, check the condition of the rollers to ensure they are functioning properly.

Don’t forget to inspect the pulleys—they play a key role in keeping the belt aligned and moving smoothly. Dirt and debris in the pulleys can cause alignment issues and affect overall system efficiency.

4. Check Alignment and Tension

Over time, your conveyor system can become misaligned, which leads to uneven wear on belts and rollers. This misalignment can cause premature damage and inefficiency. During your spring cleaning, check the alignment of the entire system and make any necessary adjustments.

Also, inspect the tension of belts. Over time, they may loosen, which can affect system performance. Ensuring that the belts are correctly tensioned is key to a smoothly operating system, reducing unnecessary strain and energy consumption.

6. Inspect for Wear and Tear

It’s crucial to inspect the entire conveyor system for any signs of damage or excessive wear. This includes the belts, rollers, and gears. If you notice any worn parts, it’s wise to replace them before they cause more serious issues. Early replacement of components can help avoid expensive repairs down the line.

7. Test the System After Cleaning

Once the cleaning and inspection are complete, run the system through several cycles to check that everything is operating smoothly. Pay attention to any unusual noises or vibrations, and watch for any signs of misalignment or other issues. Testing the system thoroughly after cleaning helps identify any potential problems before they escalate.

Consider Upgrades for Better Efficiency

Upgrading to high-quality products is a smart way to improve the efficiency of your conveyor system. Investing in better components not only reduces the need for frequent maintenance but also ensures your system operates more smoothly and reliably. High-quality belts, motors, and parts are designed to withstand more wear and tear, which means fewer repairs and longer-lasting equipment. In the long run, this can result in significant cost savings, especially by minimising downtime and boosting productivity during busy periods.

For expert advice on when to replace your conveyor belts be sure to check out our detailed guide. Keeping your system up to date is key to staying ahead of seasonal demands and ensuring maximum efficiency.

How to Keep Your Conveyor System in Top Shape

Once your spring cleaning is complete, it’s important to keep your system in optimal condition. Setting up a regular maintenance schedule can help prevent dirt build-up and address small issues before they turn into bigger problems.

Consider investing in a preventive maintenance plan. This proactive approach ensures your system remains in top shape, reducing the risk of unexpected breakdowns and increasing the overall lifespan of your equipment.

In summary, spring cleaning your conveyor system is an essential part of preparing for increased production, especially when you expect higher demand. By performing a thorough cleaning, inspecting key components, and upgrading where necessary, you can ensure your conveyor system operates at peak efficiency. This will help reduce the risk of breakdowns, lower energy costs, and prolong the lifespan of your equipment.

Whether you handle the cleaning yourself or seek professional assistance, maintaining your conveyor system is vital. With our high-quality conveyor belt products and services, we’re here to help you keep your systems running smoothly all year long.