How to Choose the Right Conveyor Belt for Your Manufacturing Process

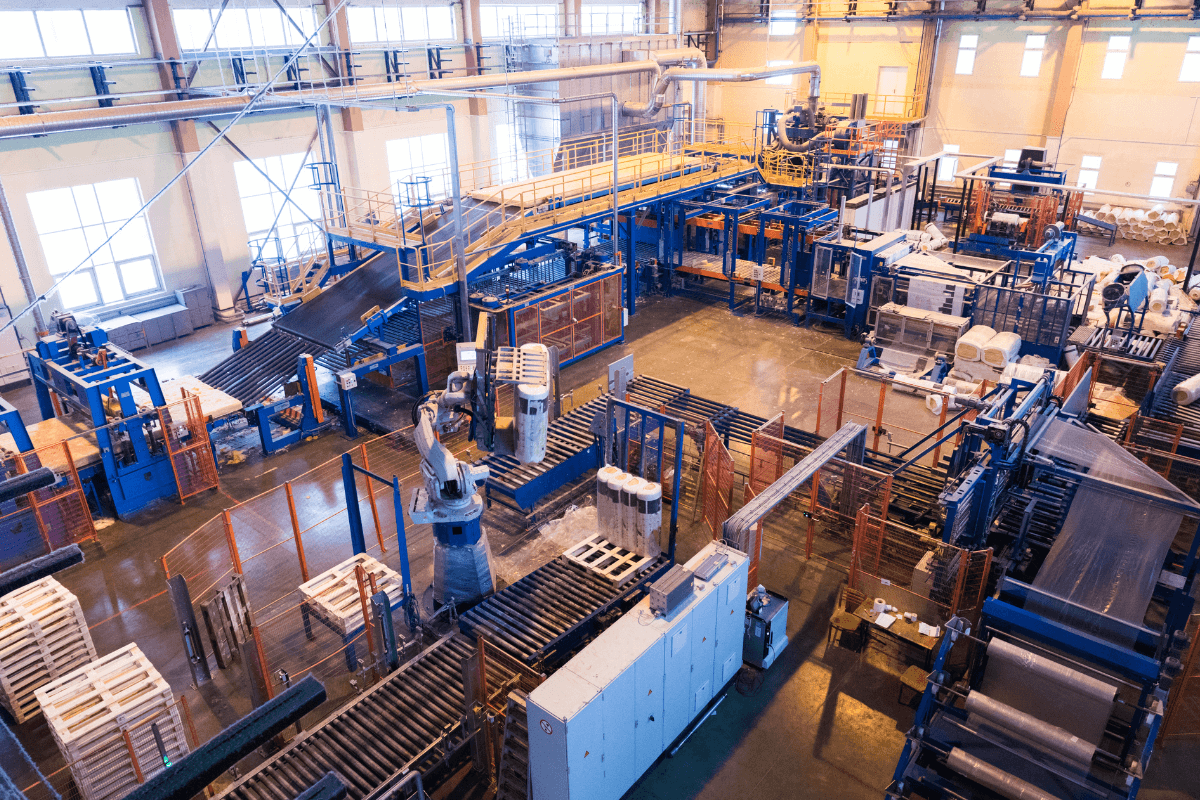

Choosing the right conveyor belt for your manufacturing process is more than just selecting a product; it’s about optimising efficiency, enhancing productivity, and ensuring safety in your operations. With a variety of conveyor belts available on the market, each tailored for specific applications, understanding your unique needs is essential. In this practical guide, we’ll delve into the key factors to consider when selecting a conveyor belt, helping you make an informed decision that suits your business.

Understanding Conveyor Belts

At its core, a conveyor belt is a continuous loop of material that transports items from one place to another within a facility. They are crucial in industries ranging from manufacturing and logistics to food processing and mining. Conveyor belts come in various types, including:

- Modular Belts: Composed of interlocking plastic modules, these belts are versatile and can navigate complex layouts, making them ideal for processing lines.

- Flat Belts: A simple, smooth surface often used for lighter loads in straightforward transport applications.

- Timing Belts: These belts have teeth that engage with gears, allowing for precise movement and timing—essential in automated systems.

Each type serves distinct purposes, and understanding these differences is the first step in making the right choice.

Factors to Consider When Choosing a Conveyor Belt

1. Material Compatibility

The materials being transported significantly influence the type of conveyor belt you need. For example, in the food processing industry, it’s crucial to use food-grade conveyor belts that meet hygiene and safety regulations. These belts are typically made from materials like polyurethane or rubber that do not contaminate the food.

If you’re transporting chemicals or abrasive materials, you’ll need a belt that can withstand exposure without degrading. Identifying the materials your conveyor will handle is essential to selecting the right composition and surface finish.

2. Load Requirements

Understanding the weight and size of your materials is crucial for selecting a conveyor belt. Conveyor belts come with different load capacities, often measured in pounds per foot (lb/ft) or kilograms per metre (kg/m).

- Lightweight Belts: Suitable for materials that weigh less than 20 pounds per foot. Ideal for small packages and items.

- Medium-Duty Belts: Can handle loads between 20 and 100 pounds per foot. Commonly used in manufacturing environments.

- Heavy-Duty Belts: Designed for loads over 100 pounds per foot. Typically found in mining or heavy manufacturing operations.

Choosing a belt that can adequately support your load without risking damage is essential for safety and efficiency.

3. Operating Environment

The environment where the conveyor belt will operate can greatly influence its performance and longevity. Consider the following factors:

- Temperature: Extreme heat or cold can affect the belt’s material properties. For instance, belts used in freezer applications should remain flexible at low temperatures.

- Humidity: High humidity levels can lead to moisture-related issues, especially in electrical components or food processing applications. Select a belt that can resist moisture if necessary.

- Chemical Exposure: If your manufacturing process involves corrosive substances, you’ll need a belt that can withstand such conditions without deteriorating.

4. Speed and Efficiency

The speed of your conveyor system can also dictate the type of belt you choose. Different applications require varying speeds, from slow-moving belts in assembly lines to high-speed belts in packaging operations.

For instance, if your operation needs to move products quickly to keep up with production demands, you might opt for a high-speed modular belt. Conversely, if precision is crucial, such as in packaging or labelling processes, a timing belt that allows for synchronised movement would be more appropriate.

Belt Specifications

Understanding the technical specifications of conveyor belts is vital in selecting the right one for your needs. Key specifications include:

- Thickness: The thickness of the belt affects its strength and durability. Thicker belts can handle heavier loads but may also be less flexible.

- Width: The width of the belt should match the size of the items being transported to prevent overflow or spillage.

- Tensile Strength: This indicates how much tension the belt can handle before breaking. Higher tensile strength is essential for heavy-duty applications.

- Friction Coefficients: The amount of grip a belt provides is crucial for preventing slippage. Higher friction materials are necessary for inclined or vertical applications.

Maintenance and Durability

Choosing a durable conveyor belt is essential for minimising downtime and repair costs. Regular maintenance not only extends the lifespan of the belt but also ensures it operates efficiently. Here are some tips to maintain your conveyor belt:

- Regular Inspections: Routinely check for wear and tear, particularly in high-friction areas or points of contact. Regularly checking your conveyor belts is vital for maintaining performance. For more insights, read our article on the importance of regularly checking your conveyor belts.

- Cleaning: Keep the belt clean to prevent build-up of materials that could affect performance, especially in food processing applications as efficient conveyor belts can significantly limit food waste.

- Alignment: Ensure the belt is properly aligned to avoid unnecessary friction or damage.

Implementing a scheduled maintenance plan can help identify potential issues before they escalate, ultimately saving you time and money.

Customisation Options

Many businesses benefit from customised conveyor belts. Depending on your operational needs, you might consider features such as:

- Cleats: These raised sections can help keep materials in place, especially on inclines.

- Sidewalls: Useful for transporting loose or bulk materials, preventing them from falling off the sides of the belt.

- Material Selection: Custom belts can be made from different materials to meet specific industry needs or performance criteria.

If your process requires unique specifications, let us know and we can offer tailored solutions can significantly enhance your operations.

Cost Considerations

When evaluating conveyor belts, consider both the initial costs and long-term value. While a cheaper belt may save money upfront, it might not last as long, resulting in higher replacement costs and potential downtime.

Assessing Total Cost of Ownership (TCO)

This includes the initial purchase price, maintenance costs, and potential productivity losses. A more expensive belt might prove more economical in the long run if it requires less frequent replacement and minimal maintenance.

Conveyor Belt Applications Across Industries

Different industries have varied requirements for conveyor belts. Here are a few examples:

- Automotive Sector: Uses timing belts for precise synchronisation during assembly, ensuring that components are delivered at the right time.

- Food Industry: Employs modular conveyor belts to navigate complex layouts while ensuring hygiene standards are met.

- Logistics and Warehousing: Often rely on flat belts for straightforward material handling in sorting and packaging applications.

Understanding these examples can help you identify the best solution for your needs.

Consulting with Experts

When in doubt, consulting with a conveyor belt specialist can provide invaluable insights into your unique operational challenges. Our team of experts can work closely with you to assess your specific requirements and recommend the most suitable options. We can analyse your production processes to identify potential bottlenecks and inefficiencies, providing tailored solutions that meet your needs. Whether you require a conveyor belt for a highly specialised application or simply need advice on optimising your existing system, we’re here to help.

In summary, choosing the right conveyor belt involves careful consideration of various factors, including material compatibility, load requirements, and operating conditions. By understanding your unique needs and consulting with experts, you can select a belt that enhances efficiency and productivity in your manufacturing process.

Ready to find the perfect conveyor belt for your business? Explore our extensive range of products, or contact us today for a personalised consultation.