The Cost of Downtime

Recent reports have shown that the global cost of unscheduled downtime across process industries is in the region of over $40 billion each year. While some downtime is avoidable, equipment failures should cause limited downtime and effective predictive maintenance can help to limit this further.

Facilities of today are far more advanced than those just ten or even five years ago, with data networks, integrated hardware and automated processes all talking together. As a result, a failure of some sort greatly impacts the production lines of a business, resulting in significant costs to fix as well as the price of the downtime itself. With some businesses seeing millions of pounds of stock pass through their conveyors each day, the impacts are sizeable.

However, a study conducted by Infraspeak discovered that over 90% of companies considered their maintenance process to lack efficiency and commented that a failure in their system could have severe consequences.

Predictive maintenance is exactly what is suggested with a proactive approach to looking after the processing network. You log and identify areas which require support and attend to them before such a failure occurs. Operatives within the manufacturing ecosystem will know that failures and breakdowns happen day in, day out, yet through predictive maintenance, you can prevent or reduce these breakdowns and ultimately help manufacturing plants achieve high-efficiency standards and deliver quality products in the process.

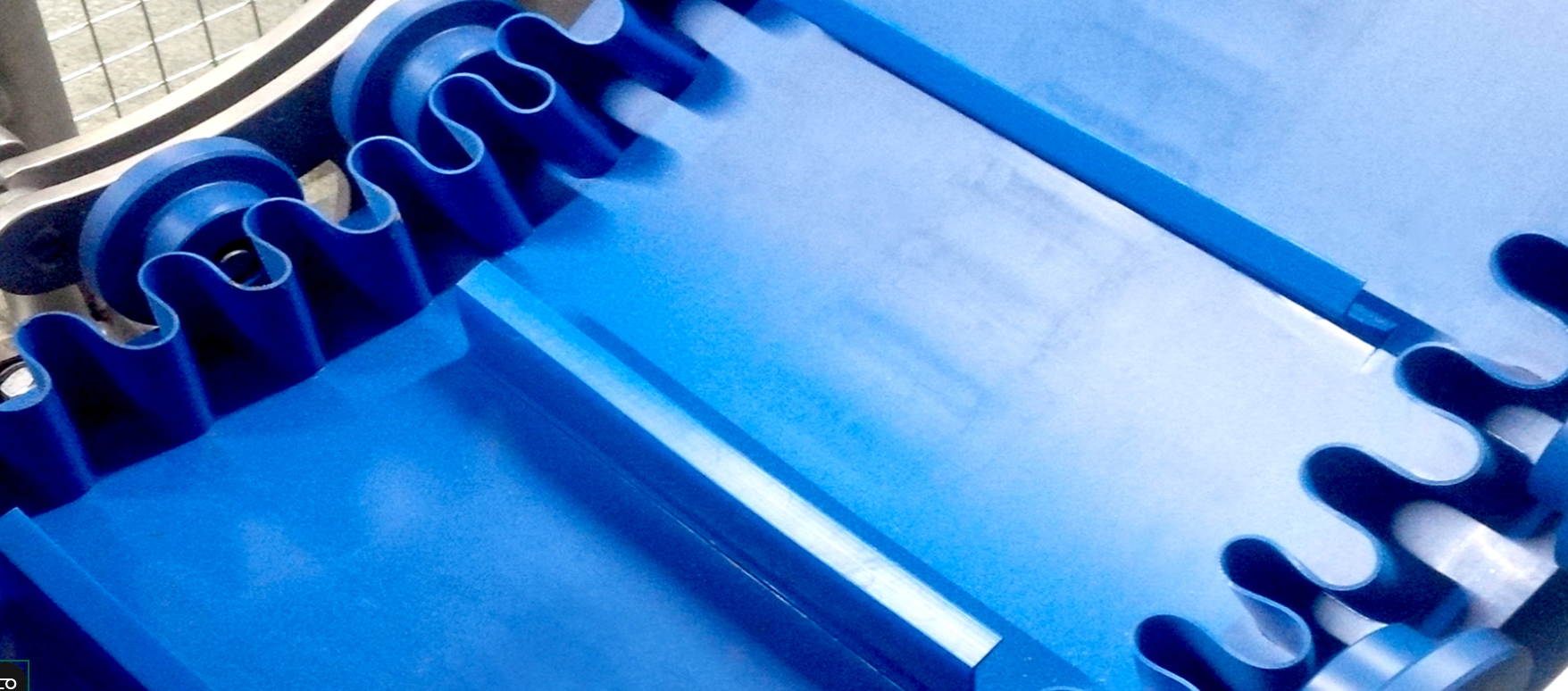

The process is very much about obtaining data and being strategic to sense danger before it occurs. Sensing and testing of the belts to ensure it is running correctly and any changes in performance are logged and monitored. This is where Chiorino can help.

If you would like to know more about how we can help reduce your downtime and your processes as simple as possible, please get in touch with one of our team.